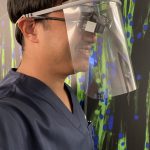

Speed trumps perfection. Safety is a priority. This coronavirus pandemic has created a tsunami of innovation and collaboration. New problems are identified and creative solutions are offered across specialty lines. Many Ear Nose and Throat Surgeons in Australia and New Zealand use a special spectacle-mounted headlight magnifying loupes to look into ears, noses & throats (Vorotek). Standard face shields are not compatible as the visor hits the headlight. I shared this problem with an orthopaedic surgeon Dr Claudia di Bella who then connected me immediately to the BioFabrication 3D Lab in Melbourne. Ten minutes of discussion of the challenges led to some simple solutions to bring the shield forward. Within 2 days, we have a prototype which was then simplified and refined. Two days after that we have a good solution to the problem. You can put this on with optical loupes up or down, which make patient examination easier. Glare from plastic is minimal and acceptable. The plastic can be detached from the frame easily to be regularly cleaned and washed. Watch it here.

Note: this face shield is a layer of splash/droplet protection over your vorotek. You still need to don other protective measures such as surgical mask (or N95 in an AGP), gowns and gloves. User feedback will improve the design and functionality for the next generation of shields we’re working on.

This is an example of how 3d printing skills are making an immediate difference to clinicians at the front lines facing the patients. Simple, cheap, scaleable solution.

Materials:

1. 200Micron thickness A4 overhead projector sheet from your local stationery shop. You can cut the length and width to size. This sheet can be wiped down with alcohol or soap at every patient encounter.

2. Hair ties, hair elastic band or velcro straps from your local shops. Velcro straps will give a bit more security if you preferred.

3. 3D printed ENT-modified frame. Drop a line at BioFab3d. They can send you the open-sourced file that has been refined by the team at RMIT and BioFab3D. Take the file to your nearest 3D printing facility. If you live in Melbourne, you can pick up the frame from the Lab situated within the campus of St.Vincent’s Health Melbourne. Cathal O’Connell is the man you want to speak to. This is his page at COVID SOS.

Click on this video on how to assemble the face shield. Too easy!

They also have the standard face shield (not modified to allow headlight. The shield sits closer to the face). They are going into production asap.

The stl file for Vorotek modified faceshield to download is here.

For the standard face shield that sits closer to the face, the file is here.

I’m grateful for innovation and collaboration. We’re all in this together.

CATHAL O’CONNELL of 3d Fabrication Lab, PAUL SPITHILL from RMIT Advanced Manufacturing Precinct & Prof MILAN BRANDT, Director of RMIT Advanced Manufacturing Precinct have donated their expertise, time and effort for free. RESPECT TO THEM. Also catch this development on SBS News. Their website here.